Steel Monopiles

As wind turbines increase in size and the industry moves into deeper water, the production of steel monopiles, by far the most popular foundation type must keep pace.

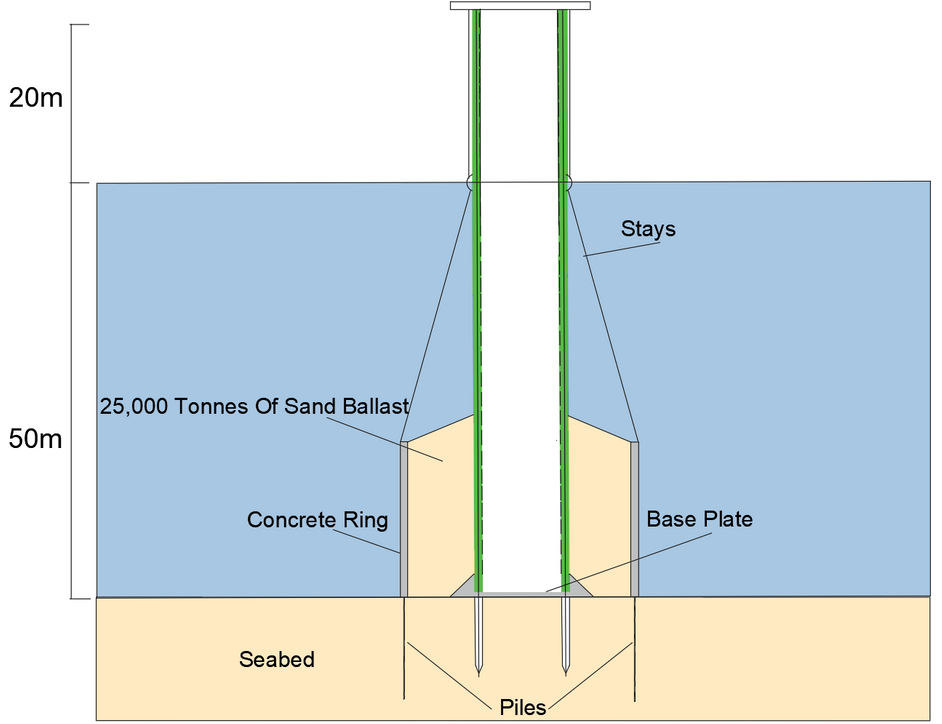

The largest monopiles are now 90m x 8m Dia and weigh 2000ts with future designs predicted to reach 120m x 15m Dia and weigh 4000ts.

Foundations of this size present a huge challenge to manufacturers and installers, a radically new approach to the construction, delivery, installation, and eventual decommissioning is required.

As most of the major components and equipment required to build an offshore wind farm are imported, The UK Plc derives little benefit from this renewables revolution, this new monopile design will allow UK companies to access a global market for off shore foundations

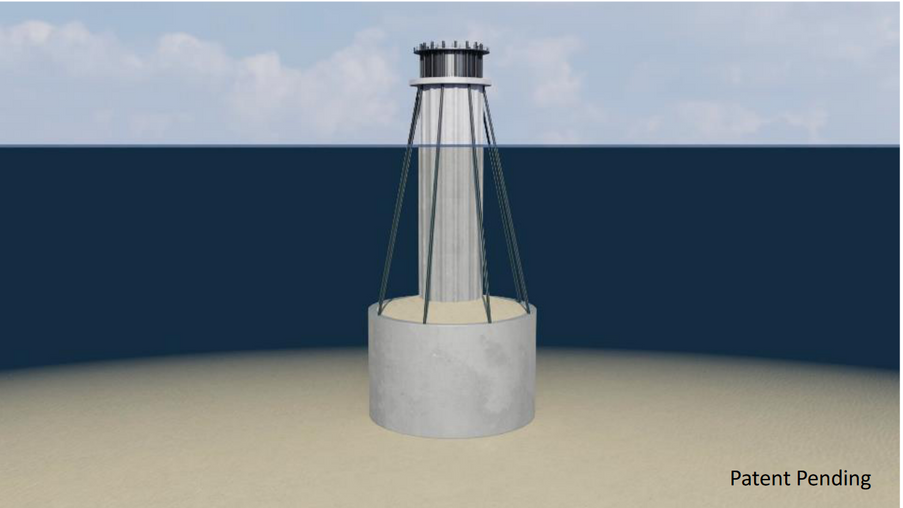

Aqua Innovations' new design addresses these issues.

Advantages

An animation of the construction / delivery / installation is available on request

Copyright © All Rights Reserved

Registered Address: 4th Floor Metropolitan House, 31-33 High Street, Inverness, IV1 1HT